The main classification of polycrystalline mullite fiber

PMF (Polycrystalline Mullite Fiber) is the latest ultra-lightweight and high-temperature insulation material in the world. It is composed of mullite microcrystals. It combines the characteristics of crystal materials and fiber materials, and has excellent thermal stability. , Using temperature 1500, melting point 1840, thermal conductivity is 1/6 of traditional refractory bricks, the bulk density is only 1/25, it is an ideal material for high temperature furnace energy saving and increase production.

Technical index

Chemical composition AI2O3: 72 ~ 74%

AI2O3 + SiO2: ~ 99.6%

Main crystal phase mullite

Fiber diameter 2-3.8μ

Specific surface area 35.5M2 / g (1000 ℃)

Reburning shrinkage rate ~ 1.0% (1500 ℃ x6hr)

Bulk density 60-100kg / M3

Working temperature 1500 ℃

Performance comparison

◆ It is made by chemical method and has a microcrystalline structure with excellent thermal stability. The use temperature exceeds 300 ~ 400. C.

◆ The fiber diameter is small and uniform, the slag ball is trace, and the product bulk density is 1/2 ~ 1/3.

◆ Big fiber, high porosity and small thermal conductivity.

◆ With large specific surface area, it is an ideal high-temperature catalytic carrier material.

PNF-100 series

The PNF-100 series is cut and compressed with polycrystalline mullite fiber felt and wrapped into blocks without any binder.

feature:

Thermal shock resistance

Low thermal conductivity

Light weight

Sound absorption performance

Low thermal storage

performance:

◆ Composition: AI2O372 ~ 75%, SiO228 ~ 25%

◆ Crystal phase: single mullite phase

◆ Melting point: 1840 ℃

◆ Operating temperature: electric furnace <1500 ℃; flame furnace <1400 ℃

◆ Specific heat: 1.24KJ / kg.k

◆ Thermal conductivity (W / M. ℃) 1000 ℃ C -0.226 1300 ℃ -0.336 1200 ℃ ~ 0.264 1400 ℃ ~ 0.384

◆ Reburning wire shrinkage: 1500. C x6hr <1.0%

◆ Capacity: 100Kg / m3

◆ Specification: 200x100x30 ~ 60mm

Application: For hot-lining lining of various high-temperature furnaces. Such as steel, chemical, machinery and other industries heating furnace, soaking furnace, forging furnace, heat treatment furnace, ceramics, building materials, electronics and other industries sintering kiln, firing kiln.

PMF-300 series

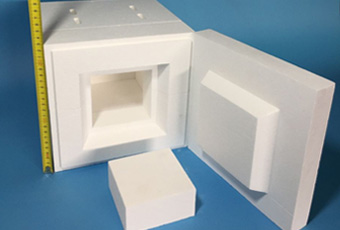

PMF-300 series is made of polycrystalline mullite fiber loose cotton with special bonding materials, and is made of elastic felts, pads, rings, or rigid plates, blocks and other special-shaped pieces by vacuum forming.

feature:

Have strength

Low thermal conductivity

Thermal shock resistance

Easy machining

Low thermal storage

Light weight

◆ Performance: Operating temperature: 1450 ℃

◆ Bulk density: 200 ~ 450 Kg / m3

◆ Reburning linear shrinkage: 1500 ℃ x1hr ~ 1.00%

◆ Thermal conductivity; (W / M. ℃)

1000 ℃ -0.16 1250 ℃ -0.22

1350 ℃ ~ 0.25

Application: high temperature resistance furnace, induction furnace, ladle cover, glass melting furnace, kiln car, high temperature radiation tube, high temperature vessel, burner boiler, etc.

Military, scientific research, aerospace, nuclear reactor and other special high-temperature parts.

PMF-400 series

PMF-400 series composite fiber is made of polycrystalline mullite fiber loose cotton and first-grade aluminum silicate fiber with special bonding materials, and is vacuum-molded to form hard bricks, boards, and tubes according to different temperature gradients. And so on.

feature:

Have strength

Low thermal conductivity

Thermal shock resistance

Easy to process

◆ Working temperature: 1450 ℃

◆ Capacity: ~ 400 Kg / m3

◆ Thermal conductivity: (W / M. ℃)

1000 ℃ -0.17 1250 ℃ –0.24

1350 ℃ -0.27

◆ Reburning wire shrinkage: 1400. C x24hr ~ 1.0%

◆ Tensile strength (Kpa)

◆ Compressive strength (Kpa) 13.01

◆ Bending strength (Kpa) 440.00 Size: Customized according to drawings

Application: high temperature resistance furnace, sensor furnace, ladle cover, hood furnace, glass melting furnace, kiln car, burner brick, etc.

Military, scientific research, aerospace, nuclear reactor and other high temperature parts.