Introduction

Polycrystalline mullite fiber and polycrystalline alumina fiber, so far two of the newest types of super-light high-temperature refractory fibers in the world, are two different products in the whole Al2O3-SiO2 Ceramic Fiber Series.The application temperature for them ranges from 1500 to 1700°C, surpassing that for glass - -state fibers by 200 to400C. Both of them can be widely applied in various areas such as pottery making, electronics, metallurgy, chemicalindustry, glass making, mechanics, astronautics and military engineering, to make the adiabatic inner lining of hightemperature industrial furnaces, so as to conserve the energy, increase the production, prolong the service life ofthe furnace, as well as improve the working conditions. As for appearance, they look very much like absorbentcottons, white, smooth, soft, and springy.

Characteristics

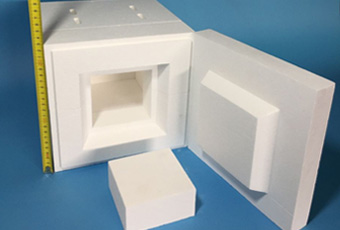

Polycrystalline mullite fiber is a unique type of Polycrystalline refractory fiber which exists in the form of mullite.The production of it requires sophisticated techniques. Such high- -technology intensity makes its productiononlypossible by certain companies in a few developed countries, like some silicon carbide companies in U.S., ICIChemicals in Britain, and some other few in Japan and Germany.The production technique of polycrystalline mullitefiber completely differs from that of glass-state fibers. It adopts the colloidal method in chemistry, following theproduction formula for the monocrystalmullite(Al2O3-SiO2),with a alumina(Al2O3)content of 72% and a silica(SiO2)content of 28%. The production process is conducted in the following steps: first, mix certain amount ofsoluble aluminum and silicon to get a colloidal fluid with certain adhesiveness, then draw off the fluid following theregular centrifugal drawing process, and finally turns it into the crystal form by heating at high temperatures to getthe mullite fibers. The conduction rate of PMF is 1/6 of that of average refractory bricks, while the bulk only 1/25 ofthat of the latter. The fiber cotton produced, which is still scattered, can be used as the stuffing material for high-temperature insulation layers. After the wet vacuum treatment, the scattered cotton can be further made into otherPMF Series products, like blocks, mats, bricks, special precast pieces, modules, components, etc.

Polycrystalline alumina fiber is a crystal fiber that mainly exists in the form of alundum. Like PMF, it is alsoproduced by the colloidal chemistry method, but the techniques involved in the production process are even morecomplex. The chemical content of it also differs from the former, with 95% of alumina (Al2O3) and 5% of silica (SiO2).The scattered fiber cotton produced can be made into blocks, bricks and special precast pieces, using the same wetvacuum method as that in the PMF products making process.

Application

High temperature environment filling, sealing and heat insulation (kiln car, pipeline, kiln door, etc.), fiber composite materials (such as friction plate, etc.), various industrial furnace linings (hot surface and back lining), building fire prevention, sound absorption, high temperature filter materials, raw materials for deep processing products (refractory fiber paper, vacuum formed felt / board or other products, etc.).

Product Common Specifications

10/20kg/piece

Zhejiang Deqing Leijing Crystal Fiber Co.,Ltd is an enterprise with wide application scope, large scale and high technology content.The products are developed from polycrystalline mullite fiber cotton to existing light-weight refractories that are suitable for high, medium and low temperature ranges,The application field has been extended to the fields of metallurgy, chemical industry, machinery, electronics, ceramics, building materials, scientific research and aerospace.

Zhejiang Deqing Leijing Crystal Fiber Co.,Ltd is an enterprise with wide application scope, large scale and high technology content.The products are developed from polycrystalline mullite fiber cotton to existing light-weight refractories that are suitable for high, medium and low temperature ranges,The application field has been extended to the fields of metallurgy, chemical industry, machinery, electronics, ceramics, building materials, scientific research and aerospace. Give full play to the scale management advantage of high and new technology industrialization,And committed to improving the technological progress of the kiln and promoting the development of the domestic industrial furnace to the environment-friendly and energy-saving trend that conforms to the international kilns.Strive to improve the living environment of mankind.

Give full play to the scale management advantage of high and new technology industrialization,And committed to improving the technological progress of the kiln and promoting the development of the domestic industrial furnace to the environment-friendly and energy-saving trend that conforms to the international kilns.Strive to improve the living environment of mankind.